History of Japan's bearing industry

1) Situation prior to World War

II

2) Postwar development

3) Current state of the industry

3-1. Internationalization

3-2. Modularization

3-3. Technical trends

1) Situation prior to World War II

It is believed that bearings were first introduced in Japan around 1910. With the onset of WWI in 1914, the demand for domestic bearing production was created, and as a result numerous Japanese bearing manufacturers were established during and shortly after WWI. The first Japanese-made bearing was manufactured in 1916. Japanese bearing development and production expanded rapidly during the period through WWII, fueled mainly by demand for military applications.

|

|

|

Japanese bearing factory around 1916

|

Ball bearing manufacturing drawing made

in Taisho era |

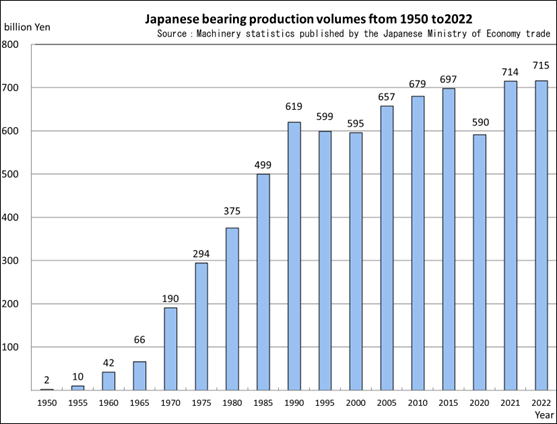

Although restrictions on production and investment were placed on Japan’s bearing industry for a short period following the war, it thereafter proceeded to grow in step with private manufacturing industries such as the automobile and home appliance industries. In 1952 the first streamlining of the bearing industry began, and in the latter half of the 1950s, such streamlining efforts were intensified, government support based on legislation was received, and the groundwork for strong growth was laid. In 1965 new JIS standards conforming to ISO standards were established, and trade began to expand. In the 70s and 80s, trade friction with the West erupted, but Japan’s bearing industry for its part was able to resolve this problem through establishing order in exports, deepening mutual understanding through dialogue with Western counterparts, and expanding overseas production.

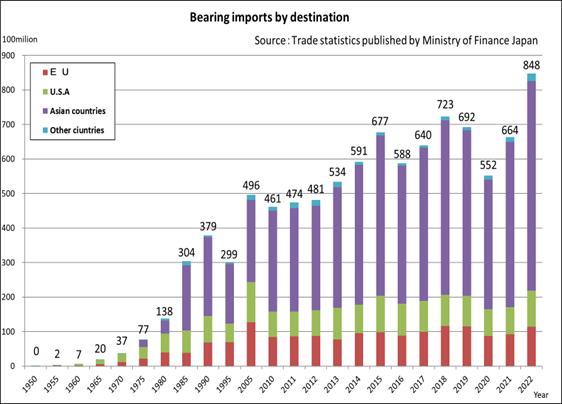

3-1. Globalization

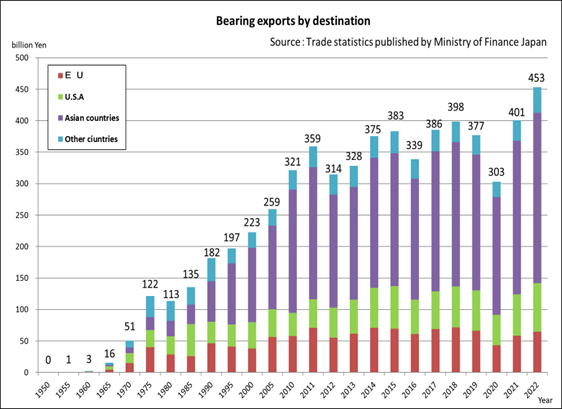

In the 1970s, Japan’s bearing industry began setting up overseas production bases—one of the first Japanese industries to begin doing so—and since 1985, the level of investment in overseas production has expanded dramatically. Although the original purpose of shifting production abroad was to alleviate trade friction, in recent years the purposes have been to achieve lower production costs, etc. In addition, Japanese bearing makers have begun setting up overseas R&D centers to support these overseas production bases. The value of annual bearing production around the world by Japanese bearing makers is approximately 800 billion yen. While there are no formal statistics, the total worldwide value of bearing production is estimated to be roughly more than 2 trillion yen, and from this we can conclude that bearings produced by Japanese bearing makers account for roughly one-third of the world’s total bearing production. Relationships with counterpart bearing industries in the West are now characterized by harmony and cooperation in contrast to former friction and confrontation. Today the JBIA participates in top-level and specialist-level meetings with the American Bearing Manufacturers Association and European Bearing Industry Federation on a regular basis to exchange information and views on issues of common concern and to carry out joint work on such tasks as the preparation of statistics, formation of countermeasures for environmental problems and imitation products, and consideration of measures to meet automotive industry trends.

Overseas bases of Japanese bearing manufacturers

3-2. Modularization and diversification

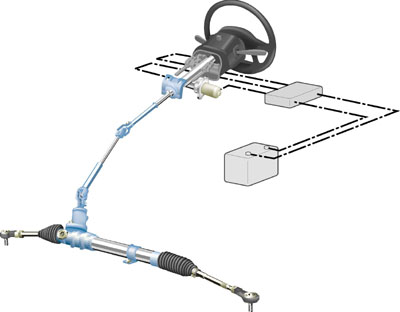

Japanese bearing makers are currently striving to create unit products and diversify product lineups. By combining bearings with peripheral parts, bearing makers are creating unit products with a single independent function while also improving compactness and ease of installation and reducing weight. Also, in order to meet the varied needs of high-tech industries, they are diversifying product lineups by developing such products as ball screws, linear guides, constant-velocity joints, electric power steering, and continually variable transmissions (CVT) through the application of bearing-related technology.

Hub units for automobile wheels

Hub units for automobile wheels

Power steering

Constant velocity joints

3-3. Technical trends

Bearing makers are developing new technology with the aim of further improving production efficiency and protecting the environment. To meet customers’ requirements, they are carrying out bearing-related research and the development of application technology in order to create bearings with improved compactness, reduced weight, greater speed capability, higher precision, longer life, and greater ability to perform satisfactorily in severe usage environments, such as extremely low and high temperatures and vacuums, as found in outer space, etc. In addition, bearing makers are providing aggressive technical service to customers from development through mass production to meet their needs during all stages.